Product Video

Technical Specification

| Model | FD850*450 |

| Max cutting area | 850mm |

| Cutting precision | ±0.20mm |

| Paper weight | 60-150g/㎡ |

| Production capacity | 120-200 times/min |

| Air pressure requirement | 0.5Mpa |

| Air pressure consumption | 0.25m³/min |

| Machine weight | 4T |

| Max paper roll diameter | 1500mm |

| Total power | 10KW |

| Dimension | 3500x1900x1800mm |

Exhibitions and Teamwork

FAQ

Q: How to go to your factory? A: It is very convenient to take a plane from Shanghai/Beijing/Guangzhou to our city “Wenzhou”. Q: What’s the payment terms? A: TT (30% deposit, the balance70% before delivery). Q: How about the delivery time? A: 45-60 working days after receiving the deposit Q: How about the warranty? A: Spare parts guarantee for one year from the date of installation. Q:How about the after-sale service? A:We can Send the technician for installation & training. But the buyer should pay the cost of air tickets and labour.

Characteristic

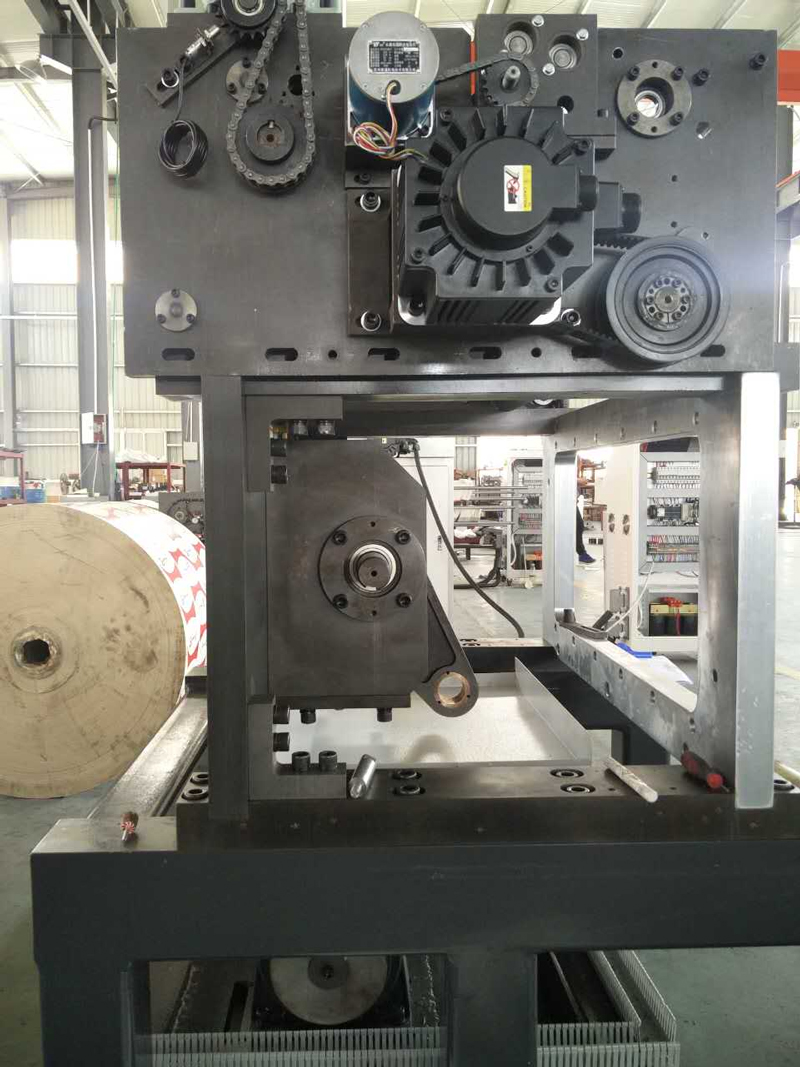

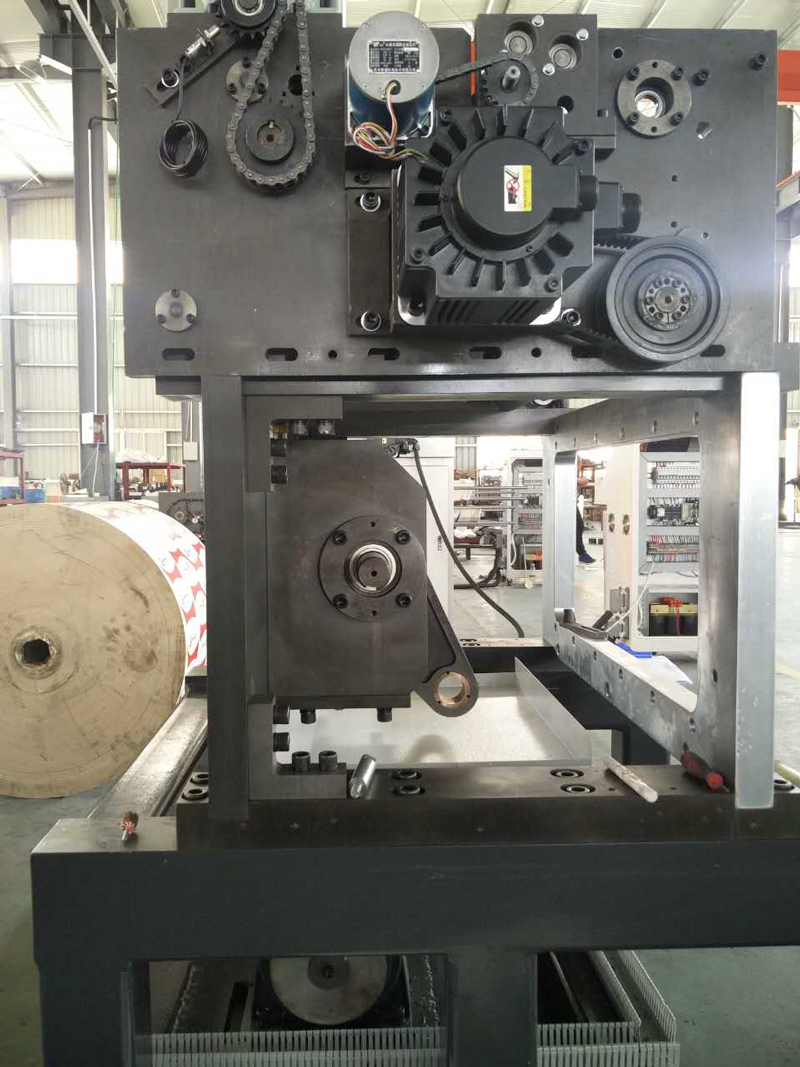

1. It adopts micro-computer, human-computer control interface, servo positioning, and we make the wallboard, base much stronger than others, it gurantees that when the machine runs with 300 strokes/min, you won’t feel that machine is shaking.

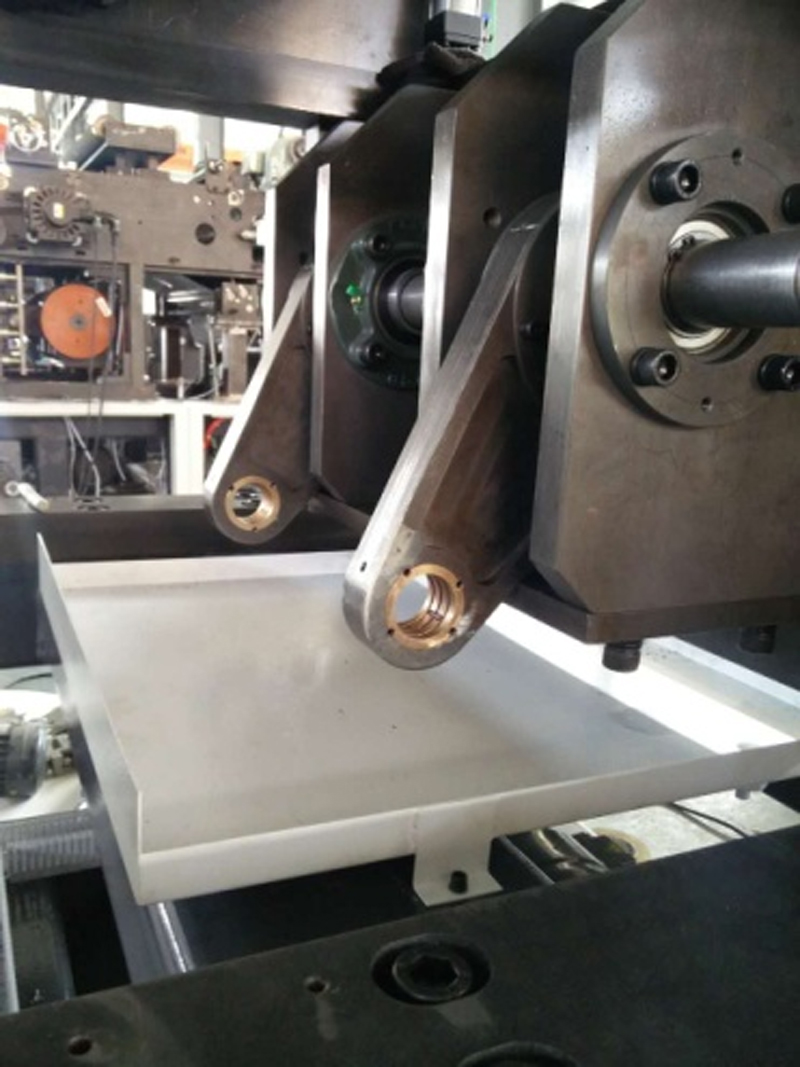

2.Lubri cation System: Adopts forced lubrication system to ensure main driving oil supply regularly and reduce friction and prolong the machine life, you could set it to lubricate one time every 10 minutes.

2.Lubri cation System: Adopts forced lubrication system to ensure main driving oil supply regularly and reduce friction and prolong the machine life, you could set it to lubricate one time every 10 minutes.

3. The die-cutting force is provided by a 7.5KW inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.

3. The die-cutting force is provided by a 7.5KW inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.

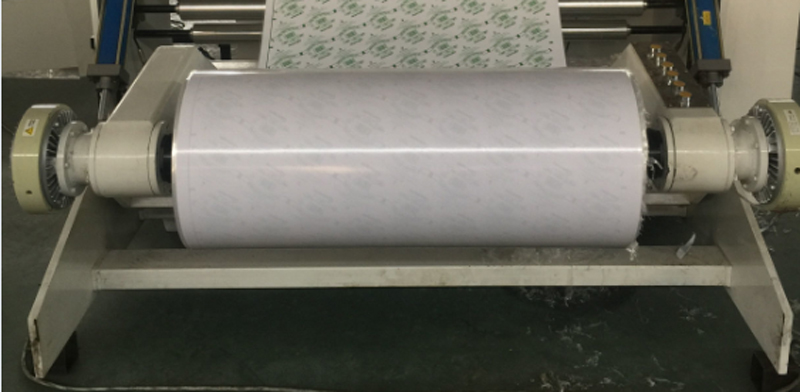

4. Feeding Unit: Adopts shaftless unwinder, tension controls unwind speed, and that’s hydraumatic, it could support at least 1.5T. Max roll paper diameter 1.5m.

4. Feeding Unit: Adopts shaftless unwinder, tension controls unwind speed, and that’s hydraumatic, it could support at least 1.5T. Max roll paper diameter 1.5m.

Punching Molds and Products