Product Video

Exhibitions and Teamwork

FAQ

Q: How to go to your factory? A: It is very convenient to take a plane from Shanghai/Beijing/Guangzhou to our city “Wenzhou”. Q: What’s the payment terms? A: TT (30% deposit, the balance70% before delivery). Q: How about the delivery time? A: 45-60 working days after receiving the deposit Q: How about the warranty? A: Spare parts guarantee for one year from the date of installation. Q:How about the after-sale service? A:We can Send the technician for installation & training. But the buyer should pay the cost of air tickets and labour.Die cutting Technical Specification

| Model | FD850*450 |

| Max cutting area | 850mm |

| Cutting precision | ±0.20mm |

| Paper weight | 150-350g/㎡ |

| Production capacity | 280-320 times/min |

| Air pressure requirement | 0.5Mpa |

| Air pressure consumption | 0.25m³/min |

| Machine weight | 3.5T |

| Max paper roll diameter | 1500mm |

| Total power | 10KW |

| Dimension | 3500x1700x1800mm |

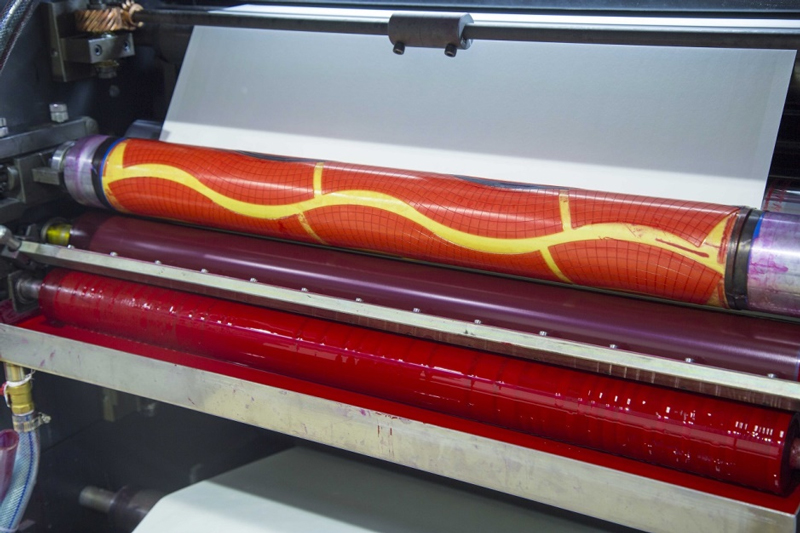

Printing Characteristics

1) Adopt the anilox roller to spread ink. 2) Unwinding tension is controlled by automatic tension controller from Japan Mitsubishi. 3) Each printing unit adopt 360°for registration. 4) Each printing unit have one IR dryer 5) The rubber roller can break away automatically while parking, and run at a low speed in order to avoid ink being dry. 6) The main motor is adopted the import stepless regulation of frequency conversion. 7) Unwinding, web guiding, printing, IR drying and punching can be finished in one processPrinting Main Technical Variables

| Web width | 860mm |

| Print width | 850mm |

| Unwind Diameter max | 1200mm |

| Press Speed max(Production speed depending on process, job etc.) | 80m/min |

| Gear Pitch | 1/8” (3.175mm) |

| Flexo Print Units (IR dryer): | 2 |

| Min.Max repeatPrint Cylinder | 10” - 22.5” |

| Web Guiding: number | 1 |

| Overprint precision | ±0.15mm |

| Machine weight | 6000kg |

| PLC | DVP28SV11T2 | Taiwan Delta |

| PLC | DVP16SP | Taiwan Delta |

| PLC | DVP04DA | Taiwan Delta |

| Servo Motor | ASDA-3023-B2 | Japan Yaskawa |

| Touch screen | TK6070IQ | Taiwan Weinview |

| Frequency Inverter | VFD055CB43A | Taiwan Delta |

| Switch | Schneider,Siemens | |

| Frequency Inverter | VFD015M43B-ZA | Taiwan Delta |

| Servo Motor | ECMA-21830RS | Japan Yaskawa |

| Main motor | CH3700-3-S-G1 | Siemence |